SOLUTION

UNIQUE & INNOVATIVE

SENSOR SYSTEM

HARDWARE

From sensor chip to information online, embedded inhouse developed system. Cutting edge technology, first of its kind in collecting and streaming data wireless in very big quantities. We dont only send data once in a while, we stream. With almost no maintenance the system is keeping track of your assets.

SOFTWARE

From firmware to operating systems and containers running applications in the cloud, An embedded solution inhouse developed to perform at the highest level of quality.

UNIQUE & INNOVATIVE

SENSOR SYSTEM

HARDWARE

From sensor chip to information online, embedded inhouse developed system. Cutting edge technology, first of its kind in collecting and streaming data wireless in very big quantities. We dont only send data once in a while, we stream. With almost no maintenance the system is keeping track of your assets.

SOFTWARE

From firmware to operating systems and containers running applications in the cloud, An embedded solution inhouse developed to perform at the highest level of quality.

Multiple overlap measurements of a longitudinal level event in wavelength D1.

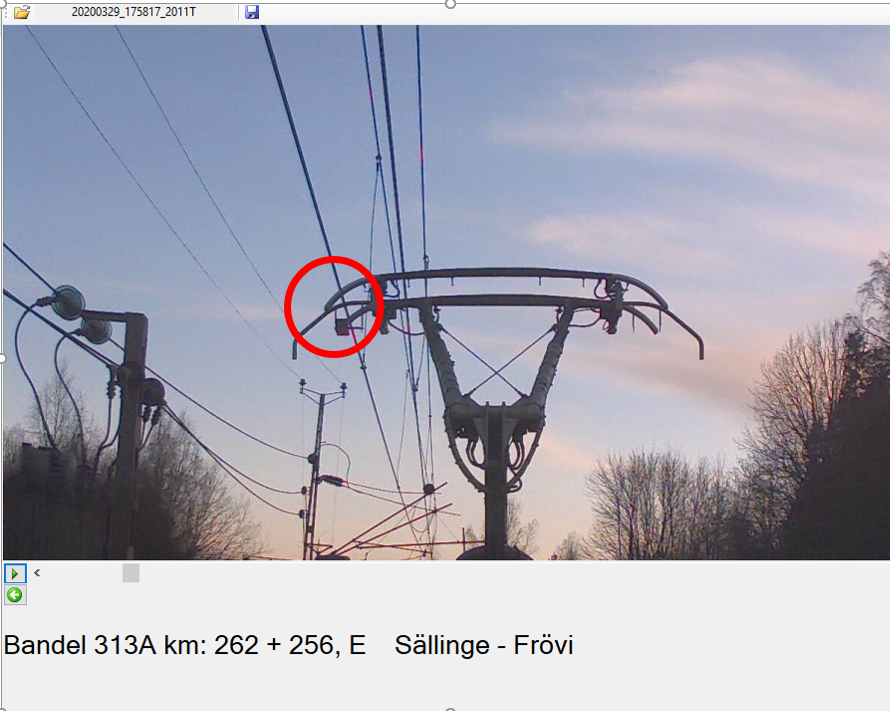

ALARMS

Algorithms are created continuously to find deviations in the infrastructure, such as defects on overhead wire or track geometry. Alarms are pinpointed to a geographical position with the accuracy of less than two meters. Triggered alarms can be monitored for possible development toward higher levels. A repair is easily followed up as feedback in the dashboard by new measurements from the same position.

Using cross-reference of algorithms and sensor behavior between customers, a railway owner in Europe can benefit from the constantly evolving algorithms even if the data is originally used in India or the US. Trigger levels or thresholds can be modified for each customer.

Alarm examples:

ALARMS

Algorithms are created continuously to find deviations in the infrastructure, such as defects on overhead wire or track geometry. Alarms are pinpointed to a geographical position with the accuracy of less than two meters. Triggered alarms can be monitored for possible development toward higher levels. A repair is easily followed up as feedback in the dashboard by new measurements from the same position.

Using cross-reference of algorithms and sensor behavior between customers, a railway owner in Europe can benefit from the constantly evolving algorithms even if the data is originally used in India or the US. Trigger levels or thresholds can be modified for each customer.

Alarm examples:

Overhead wire

Absolute height, stagger, arcing, relative wear, defects, tension, inclination, acceleration.

Track

Track geometry, longitudinal level (EN13848-2), twist, super elevation, Corrugation, Flange contact, accelerations, frequency spectrums, undermination, RCF

Balises

Relative function, balise frequency, balise amplitudes, balise messages

Position

All measurements of the same alarm is shown with individual information and all measurements get a unique position. This makes it possible to interpolate the position of the alarm down to +/- 1 meter in accuracy.

Repeatability

Every individual measurement, each passing of the position of the alarm, will be shown in graph. The repeatability is clearly shown to demonstrate that there is no doubt about probability of each alarm.

False positives

Each alarm in the dashboard is triggered after 2 individual measurements to make false positives impossible

Overhead wire

Absolute height, stagger, arcing, relative wear, defects, tension, inclination, acceleration.

Track

Track geometry, longitudinal level (EN13848-2), twist, super elevation, Corrugation, Flange contact, accelerations, frequency spectrums, undermination, RCF

Balises

Relative function, balise frequency, balise amplitudes, balise messages

Position

All measurements of the same alarm is shown with individual information and all measurements get a unique position. This makes it possible to interpolate the position of the alarm down to +/- 1 meter in accuracy.

Repeatability

Every individual measurement, each passing of the position of the alarm, will be shown in graph. The repeatability is clearly shown to demonstrate that there is no doubt about probability of each alarm.

False positives

Each alarm in the dashboard is triggered after 2 individual measurements to make false positives impossible

TRAINS

All trains equipped with sensors are shown online with position and complete system information. When the train drives data is automatically streamed to cloud. All systems are monitored with regard to functionality, calibration (which is done automatically), maintenance need such as battery charging.

INSTALLATION

Any train can be easily equipped with D-RAIL sensors. And provide measurement train quality track geometry parameters. No modification, no inauguration, no optical, almost no maintenance. Installed in hours on any rolling stock or locomotive.

Blue line = Measurement train EN13848

SENSORS

Our sensors are developed with cutting edge technology to be completely train independent and non-intrusive. The design enables minimum maintenance and top performance, while they are quickly and easily installed to measure the status of tracks, catenary and signal system.

The sensors are completely autonomous and can be powered from the train or with a battery life of up to 2,5 years depending on operation, without energy harvesting. With an energy harvesting circuit (magnetic field harvesting), the battery lifetime can be extended to infinity. Without energy harvesting, the sensor is charged on the train inside the depot and will be fully charged within hours.